¿Qué es un freno de presión Tandem CNC?

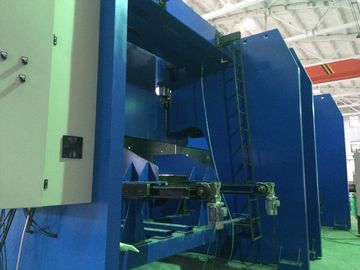

A. NoFreno de presión en tándem CNCEs una máquina especializada de trabajo de metales diseñada para realizar una flexión de precisión en hojas grandes de metal.dos máquinas sincronizadasEl trabajo conjunto para manejar trabajos más grandes y complejos permite a los fabricantespiezas de trabajo largas o largasque de otro modo sería demasiado difícil o lento de doblar con un solo prensado de freno.

La máquinaCapacidades de CNCpermitir quecontrol muy precisoEl uso de controles digitales permite a los operadores ajustar con precisión parámetros como el ángulo de flexión, la velocidad y la fuerza, lo que mejora la repetibilidad y reduce el riesgo de errores.programa secuencias de flexión complejasy garantizarcalidad constantedurante todo el proceso de producción.

¿Cómo funciona?

La configuración del freno de prensa tándem incluye dos unidades de freno de prensa independientes dispuestas en tándem, cada una equipada con controles CNC. Estas unidades están sincronizadas para trabajar en la misma pieza de metal,que les permite aplicar fuerzas de flexión simultáneamente en un área de trabajo más grandeAl dividir la carga entre dos máquinas, el sistema de tándemAumenta la eficienciay reduce la tensión de la maquinaria, lo que lleva a una mayor vida útil y menos mantenimiento.

ElSistema CNCLa integración de las dos máquinas permite ajustes precisos y garantiza que el proceso de flexión se lleva a cabo con exactitud.sistemas automatizados de manipulación de materialessimplifica aún más el funcionamiento, minimizando la intervención manual y reduciendo el tiempo necesario para completar cada tarea.

Ventajas clave de los frenos de presión en tándem CNC

-

Mejor productividad

Con capacidad para manejar piezas de trabajo más grandes y realizar una flexión simultánea en ambos lados del material,Frenos de prensas tándem CNCLos fabricantes pueden procesarMás piezas en menos tiempo., reduciendo los ciclos de producción y aumentando la capacidad global.

-

Precisión y exactitud

ElTecnología CNCse utiliza en los frenos de prensa en tándem garantizacon un valor de producción superior al 20% del valor del productoEsta precisión reduce al mínimo el desperdicio de material, reduce el reelaboramiento y mejora la calidad general de los productos terminados.

-

La flexibilidad

Los frenos de prensa tándem se pueden programar fácilmente para manejar diferentes materiales, espesores y ángulos de flexión, por lo que son muy versátiles.Acero inoxidable, aluminio u otros metales, la máquina puede ajustar los ajustes para satisfacer los requisitos específicos del proyecto, por lo que es ideal para una amplia gama de industrias.

-

Reducción de los costos laborales

La automatización y la sincronización del sistema de frenado de presión tándem reducen la necesidad de intervención manual.Las empresas pueden reducir sus costes laborales al tiempo que garantizan un proceso de producción más consistente y fiable.

-

Mejora de la seguridad

Los frenos de prensa CNC modernos están equipados con avanzadoscaracterísticas de seguridadcomo por ejemploSensores láserycortinas ligerasEstas características son fundamentales en entornos de gran volumen donde los equipos de metalurgia pueden suponer riesgos significativos.

Industrias que se benefician de los frenos de prensa simultáneos CNC

La versatilidad y la eficiencia de los frenos de prensa tándem CNC los han hecho indispensables en varias industrias, incluidas:

-

Automóvil: Fabricación de componentes de automóviles como paneles de carrocería, soportes y marcos, donde la precisión y la producción en gran volumen son críticas.

-

Aeronautica y aeroespacial: Doblaje de metales de alta resistencia utilizados en la construcción de aeronaves y piezas aeroespaciales, que requieren una extrema precisión y control de calidad.

-

Construcción: Producción de componentes estructurales, como vigas, columnas y refuerzos, a menudo de materiales pesados.

-

Fabricación de metales: Las operaciones generales de fabricación y metalurgia se benefician de la capacidad de procesar piezas grandes y complejas con mayor rapidez y precisión.

El futuro de los frenos de presión en tándem CNC

A medida que la fabricación continúa evolucionando,Frenos de prensas tándem CNCLas innovaciones en el sector de la salud y la saludAutomatización impulsada por IA,manipulación de materiales por robots, yaprendizaje automáticoestán listos para aumentar aún más las capacidades de los frenos de prensa tándem, haciéndolos más intuitivos, más rápidos y capaces de procesar piezas aún más complejas con una intervención humana mínima.

Por otra parte, la integración defábrica inteligenteLas nuevas tecnologías permitirán el seguimiento de datos en tiempo real y el mantenimiento predictivo, asegurando que las máquinas funcionen siempre con la eficiencia óptima.piezas metálicas personalizadas y complejasLos frenos de prensa tándem CNC desempeñarán un papel fundamental en la respuesta a los desafíos de la fabricación moderna.

Conclusión

ElFreno de prensa tándem CNCrepresenta un avance significativo en el campo de la flexión de chapa metálica, ofreciendo a los fabricantes una solución más eficiente, precisa y flexible para el procesamiento de piezas grandes y complejas.A medida que la tecnología continúa evolucionando, las capacidades de estas máquinas solo se expandirán, convirtiéndolas en una herramienta invaluable en industrias que van desde la automoción hasta la aeroespacial.Para los fabricantes que buscan mantenerse a la vanguardia en el mercado competitivo, la inversión enSistemas de frenos de prensa tándem CNCLa Comisión considera que la aplicación de las normas de calidad es un paso hacia un aumento de la productividad, la calidad y la rentabilidad.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!